At Peli Products, we have already distinguished our company for excellence in product development and as a leading manufacturer of multi-use products. We create durable, reliable products that last a lifetime, thereby reducing our ecological impact. Now we’re on a mission to become a leader in sustainability.

We have implemented numerous initiatives at our plants around the globe to reduce waste, reuse materials, and recycle every scrap of eligible material. We are integrating sustainability into our business decisions on a daily basis. At Peli, it is our mission to protect what you value, and this includes the environment around us. Peli protects all that you value.

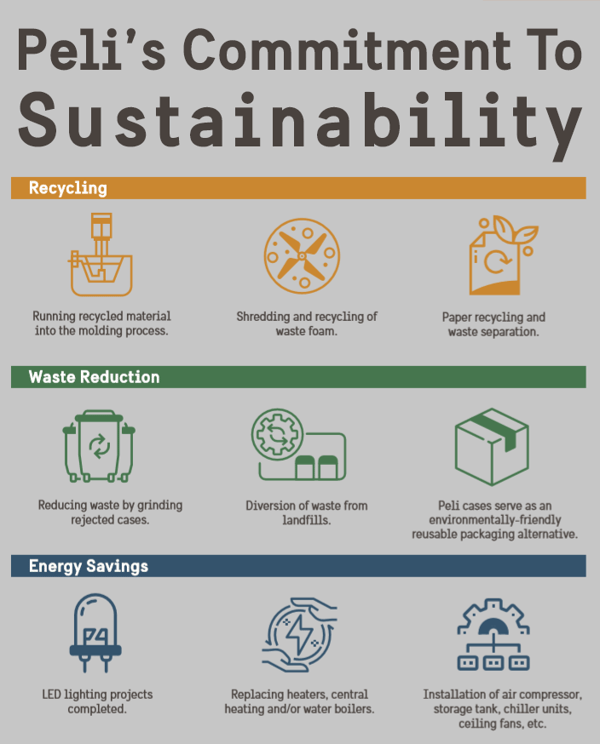

How is Peli striving for sustainability?

Peli is commited to continually improving its sustainability efforts across the organisation. Peli's focus in recent years has been on recycling, waste reduction and energy savings. This post highlights global efforts across the UK and Europe, Middle East & Africa (EMEA) regions.

Prioritization of Sustainability Efforts in the UK

In Ashford, UK, there are several sustainability efforts that are being prioritized:

- The foam shredder recycles waste foam and diverts from landfills to products made from recycled foam. The actual diversion from the landfill is 113,988 feet³.

- New central heating boilers to replace the old heater, two shutter door air curtains and ten ceiling fans have been installed. The result is a 20% reduction in electricity usage and 54% reduction in gas usage Y-o-Y 2017/2018 to 2018/2019.

- Other 2019 energy-savings projects include replacing the unit 3 shop floor heater, the central heating and water boilers.

- The 2020 energy-savings project aims to install motion sensor light switches in the office space and canteen areas to reduce electricity consumption.

The BioThermal team in Leighton Buzzard, U.K. has also focused on numerous sustainability efforts:

- Sodium lights were replaced with LED lights in the manufacturing, assembly, lab and warehouse areas. This dropped the current annual running costs by 42%.

- In addition, the team aims to reduce landfill waste by recycling and the segregation of waste. Cardboard and clear plastic wrap is recycled using a bailer. Wooden pallets are also recycled and reused. The annual rebate is approximately £10,000.

- Phase-changing material (PCM) intermediate bulk containers (IBCs) are sent for re-use, resulting with an annual rebate of £9,360. The proposed 2020 project is to re-use PCM from waste products using a filter press.

- New light sensors were installed in the offices.

- The proposed new lighting system has the added benefit of reducing Co2 emissions by 31,028 kilograms per year.

- All scrap expanded polystyrene (EPS) is returned to the supplier for recycling.

- Regarding Coolpac, all wastewater-based solutions are re-used through the manufacturing process.

Sustainability Initiatives in Europe, Middle East & Africa

The Peli Europe, Middle East, and Africa (EMEA) team boast the following sustainability initiatives:

- Goods are stored and distributed in modern warehouses (3PL Contract Logistics, 3PL Flex, Danzas DHL Dubai) that comply with the highest requirements for sustainability – including solar panel roofing, rainwater collection, maximum use of daylight and automated dimming LED lighting.

- The Edelweiss program for European production of injection-molded cases at HVB (contract manufacturing facility in Crottendorf, Germany) has reduced our carbon footprint for ocean freight from the U.S. to Europe by a volume of 50%.

- Waste separation and paper recycling at EMEA offices.

Find out how the rest of the Pelican Products, Inc. corporation is committing to sustainability around the world by clicking on the button below.

.png)

Post a comment