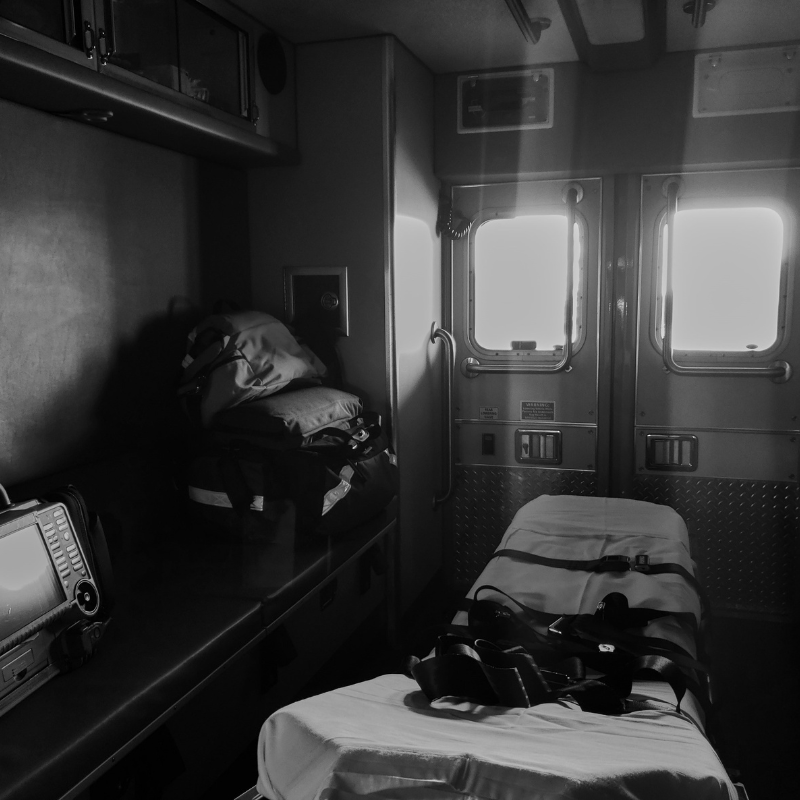

Medical Aid Teams face enormous logistical challenges when deploying into disaster zones. From diagnostic tools and sterile equipment to medication and blood samples, the diversity of supplies demands more than just protection — it demands smart organization. Yet many standard protective cases fall short due to one crucial limitation: lack of modularity.

When every second matters, rummaging through cluttered containers or transporting multiple cases for similar items is not just frustrating — it's a risk.

-1.png?width=800&height=419&name=1200%20x%20628%20px%20-%20%20(10)-1.png)

1. Why do many protective cases fail to accommodate different types of medical supplies effectively?

Most traditional protective cases are designed with fixed interiors or basic foam cut-outs, which can work well for singular item types but offer little versatility. This becomes a real problem when teams carry a mix of gear — fragile diagnostics next to vials of medication or bulky PPE beside fine surgical instruments.

Inflexible interiors lead to poor space utilisation and increased risk of damage due to movement during transit.

2. Are there case systems available that offer flexible, modular interiors for medical missions?

Yes — and they’re a game-changer. Advanced case solutions now incorporate customisable interiors like TrekPak™ dividers, Pick N Pluck™ foam, and padded divider sets. These allow teams to reconfigure layouts based on the mission, the gear, and even changes on the ground.

Some EMS-specific cases come with stackable trays and tiered compartments, designed specifically for triage organisation and rapid access. These modular features can be adjusted as medical kits evolve or field needs shift.

3. How can modularity improve field efficiency and organisation in high-stress environments?

In an emergency, speed and clarity save lives. A modular case ensures that each item has a dedicated space, clearly visible and instantly accessible. This eliminates the chaos of digging through bags or misplacing critical tools.

Additionally, modular cases enable teams to segment their kits logically — diagnostics in one layer, trauma gear in another, medications clearly labelled — supporting better workflows and less downtime during treatment.

4. What types of modular insert options are best for medical gear?

For general use, padded dividers with Velcro® connections are ideal. They’re soft enough to protect sensitive items, yet adjustable enough to accommodate new layouts.

For more structured setups, TrekPak™ systems allow precise layout control using rigid dividers and steel U-pins. These are excellent for keeping items upright, secure, and visible.

Foam systems like Pick N Pluck™ are perfect when the shape of the item is known in advance, and you need a snug fit. Many teams even use a combination of systems to strike a balance between flexibility and protection.

5. Can modular protective cases evolve with changing medical team needs over time?

Absolutely. That’s the beauty of a modular system — it adapts as your gear list evolves. If your mission changes from emergency trauma care to long-term public health, the same case can be reconfigured with new inserts. This reduces the need to purchase entirely new equipment and allows for better standardisation across team members and deployments.

Moreover, having a modular foundation supports better inventory control, quicker packing, and more efficient team training.

In high-pressure medical deployments, flexibility isn’t optional — it’s essential. Modular protective cases offer medical professionals the control, organisation, and adaptability they need to meet any challenge head-on.

Explore flexible case solutions built for mission-critical adaptability at www.peli.com.

.png)

Post a comment